COPPER ALLOYS

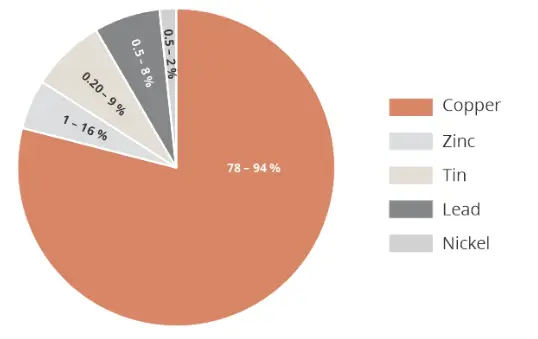

Copper has been an essential element to mankind since the prehistoric age because of its unique properties like ductility, good electrical and thermal conductivity, strength and corrosion resistance.

In order to expand on these properties, copper can be alloyed with other metals, resulting in a range of alloys that can be made to fit almost any application in the modern world.

Further on this page, you can see a huge range of such copper-based alloys that we can provide either from our stock or on a considerable lead time from our foundry. In case you cannot find what you are looking for, please feel free to contact us, enabling us to work on those alloys which can be modified to the client's specification.

DESCRIPTION

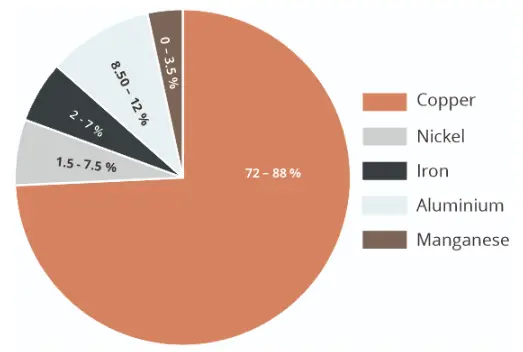

Alloys of Copper, Aluminium and Nickel are known as Nickel Aluminium Bronze alloys. Together with other alloying additions, it produces a range of properties that are beneficial to a diversified range of industries.

The Nickel Aluminium Bronze alloys are classified as alloys containing 7 to 13 % Aluminium and up to 7% Iron and 7% Nickel. Manganese upto 2.50% is added to act as a deoxidizing and strengthening agent.

PROPERTIES:

Nickel Aluminium Bronzes have a greater resistance to cavitation erosion than cast steel. Aluminium, in conjunction with Iron and Nickel, acts as a strengthener in these alloys.

The addition of Nickel improves the corrosion resistance of the already versatile Aluminium Bronze alloys.

Nickel Aluminium Bronze alloys have good resistance to fatigue and creep, ensuring usage at elevated temperatures with a long service life.

Chemical Composition

C-95500

Material Grade

C-95410

C-95800

0.1

ELEMENT

Min (%)

Max (%)

ELEMENT

Min (%)

Max (%)

ELEMENT

Min (%)

Max (%)

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

Mg

78

10

3

3

11.5

5

5.5

3.5

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

83

10

3

1.5

11.5

5

2.5

0.5

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

79

8.5

3.5

4

0.8

9.5

4.5

5

1.5

0.3

Mg

Mg

AB-2

ELEMENT

Ol

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

Min (%)

Max (%)

Balance

8.8

5.5

4

4

10

5.5

3

0.5

0.05

0.1

0.1

0.3

CB-333G

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

Mg & Cr

Min (%)

Max (%)

76

10.5

83

8.5

5.5

4

6

4

2.5

0.5

0.03

0.1

0.1

0.05

CB-334G

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

Mg

Min (%)

Max (%)

72

12

81.5

10.3

7

4.2

4.3

2.5

7.5

0.4

0.04

0.2

0.1

0.05

CuAl10

Fe5Ni5

C-63000

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

Mg

Min (%)

Max (%)

76

10.5

83

8.5

5.5

4

6

4

3

0.5

0.03

0.1

0.1

0.05

Mg

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

Min (%)

Max (%)

Balance

9

4

11

2

5.5

4

1.5

0.3

0.2

0.25

DESCRIPTION

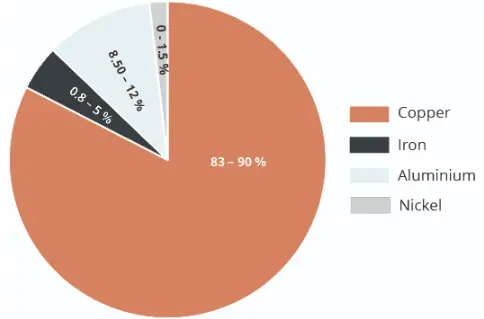

Aluminium Bronze are a family of copper-based alloys which uses Aluminium as the Principal Alloying element.

Unlike nickel-aluminium bronzes, these alloys contain Nickel only up to 1.50%.

They have strength comparable to that of mild steel and find their application in a wide range of industries.

Aluminium Bronzes comprise a wide range of compositions and alloys that can be chosen with a wide range of properties to suit many types of applications.

PROPERTIES:

Aluminium Bronzes are used for their combination of high strength and excellent corrosion and wear resistance in sea water.

These alloys are recommended for high load and high wear applications that require good ductility, weldability and exceptional resistance to fatigue.

They exhibit low rates of scaling in atmospheric conditions and can be used in environments that are far more aggressive than tolerated by most other metals.

Chemical Composition

AB-1

Material Grade

C-95200

C-95300

ELEMENT

Min (%)

Max (%)

ELEMENT

Min (%)

Max (%)

ELEMENT

Min (%)

Max (%)

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

OI

8.5

1.5

10.5

3.5

1

1

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

86

8.5

2.5

9.5

4

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

86

9

0.8

11

1.5

OI

OI

C-95400

ELEMENT

OI

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

Min (%)

Max (%)

10

5

3

11.5

1.5

0.5

C-95420

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

OI

Min (%)

Max (%)

83.5

12

10.5

5

3

1.5

0.5

CB-331G

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

OI

Min (%)

Max (%)

83

10.5

89

8.7

3.3

1.5

1

1.5

0.5

0.03

0.2

0.15

IS-3091

C-62300

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

OI

Min (%)

Max (%)

11

9

5

4

0.5

OI

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

Min (%)

Max (%)

Balance

8.5

4

10

2

1

0.5

0.6

0.25

Balance

0.5

0.05

0.1

0.25

0.3

83

Balance

0.1

Note: OI Means Other Impurities

DESCRIPTION

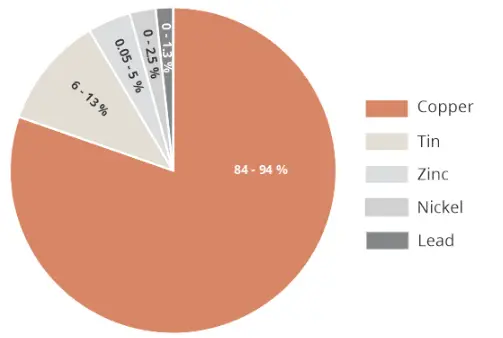

Tin Bronze Alloys are copper-based materials with Tin being the major element added to Copper. These alloys of Copper and Tin were the first to be developed four thousand years ago.

Tin's Principal function is to strengthen these alloys. Tin Bronzes are classified as alloys containing 8 to 13% Tin with only minor additions of Lead.

Other alloying elements like Nickel, Zinc, Phosphorous are added to achieve useful properties like Hardness, Machinability, Ductility and High Mechanical Properties.

PROPERTIES:

Tin Bronzes with higher tin content possess stronger mechanical properties. Tin Bronzes are stronger and more ductile than red brass or semi-red bronzes.

This combination of properties allows them to carry a high load-carrying capacity and good wear resistance.

These alloys have improved resistivity towards corrosion resistance in seawater and brines.

Chemical Composition

BC-2

Material Grade

BC-3

CuSn8

ELEMENT

Min (%)

Max (%)

ELEMENT

Min (%)

Max (%)

ELEMENT

Min (%)

Max (%)

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si & S

Sb & P

0.01

0.2

1

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

86.5

0.01

0.2

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si

0.1

P

CuSn10Zn2

ELEMENT

Sb & P

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

S

Min (%)

Max (%)

0.2

1

0.2

CuSn11P

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

S & Sb

P

Min (%)

Max (%)

87

0.01

0.1

0.1

0.05

CuSn12

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si & S

Sb & P

Min (%)

Max (%)

85

0.01

88.5

0.2

0.2

2

0.5

0.7

13

0.01 & 0.05

CuSn12Ni2

CC-480K

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si & S

Sb & P

Min (%)

Max (%)

0.01

0.2

0.2

Sb & P

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si & S

Min (%)

Max (%)

0.2

0.01

2

0.2

11

0.02 & 0.05

5

1

9

0.01

0.2 & 0.05

86

90

3

7

89.5

1

3

1

1

11

9

0.01

0.2 & 0.05

Sb & P

Balance

0.2

0.2

0.02

7.5

8.5

0.01

0.4

Balance

1

3

1.3

8.5

11

0.1

0.3 & 0.05

89.5

0.05

0.25

10

11.5

0.01 & 0.3

0.05

11

0.15 & 0.6

84.5

87.5

2.5

1.5

0.4

0.3

11

13

0.01 & 0.05

0.1 & 0.4

- & 0.05

88

90

0.5

1

9

0.2 & 0.2

CC-483K

ELEMENT

Cu

Al

Fe

Ni

Mn

Zn

Pb

Sn

Si & S

Sb & P

Min (%)

Max (%)

85

0.01

88.5

0.2

2

0.2

0.5

0.7

11

13

0.01 & 0.05

0.15 & 0.6

C-90200

ELEMENT

Cu

Al

Fe

Ni

Min (%)

Max (%)

91

0.005

94

0.2

0.5

Zn

Pb

Sn

Si

S

Sb & P

0.5

0.3

8

6

0.005

0.05

0.2 & 0.05

C-90500

Sb & P

ELEMENT

Cu

Al

Fe

Ni

Zn

Pb

Sn

Si

S

Min (%)

Max (%)

86

0.005

89

0.2

1

1

0.3

3

9

0.005

11

005

0.2 & 1.5

C-90700

C-90800

C-91700

ELEMENT

Cu

Al

Fe

Ni

Zn

Pb

Sn

Si

S & Sb

Sb & P

Min (%)

Max (%)

88

0.005

99

0.15

0.5

0.5

0.5

10

0.005

12

0.05 & 0.2

0.3

1.5

Sb & P

S

ELEMENT

Cu

Al

Fe

Ni

Zn

Pb

Sn

Si

Min (%)

Max (%)

85

0.005

89

0.15

0.5

0.25

0.25

11

0.005

13

0.05

0.2 & 0.3

Sb & P

ELEMENT

Cu

Al

Fe

Ni

Zn

Pb

Sn

Si

S

Min (%)

Max (%)

84

0.005

87

0.2

1.2

0.25

2

0.25

11.3

0.005

12.5

0.05

0.2 & 0.3

Note: OI Means Other Impurities

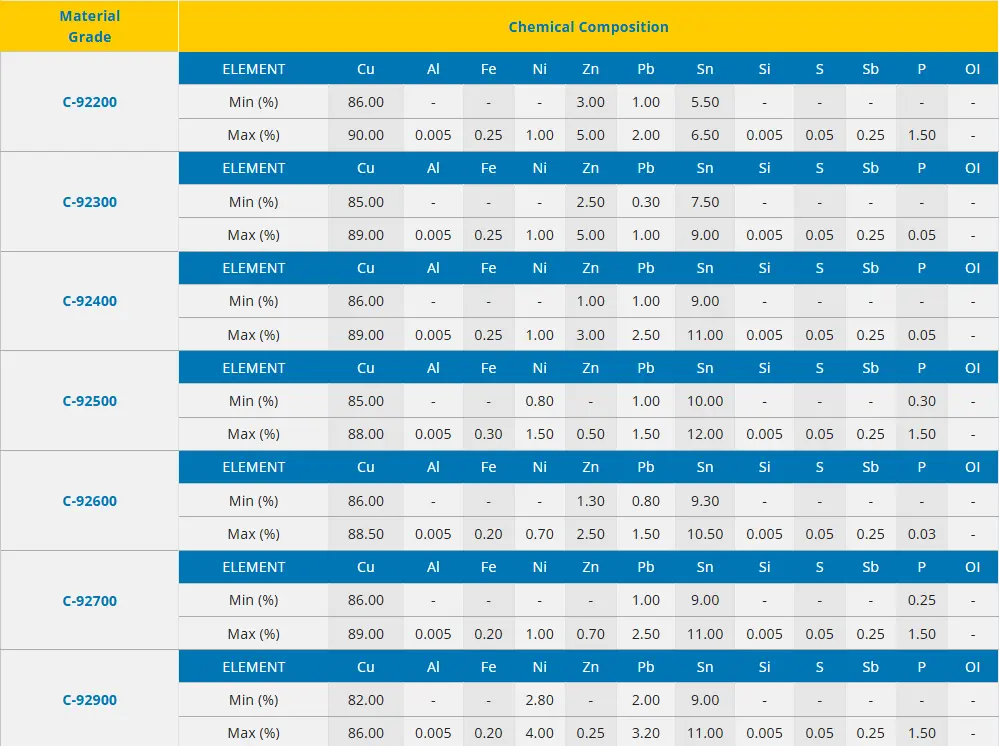

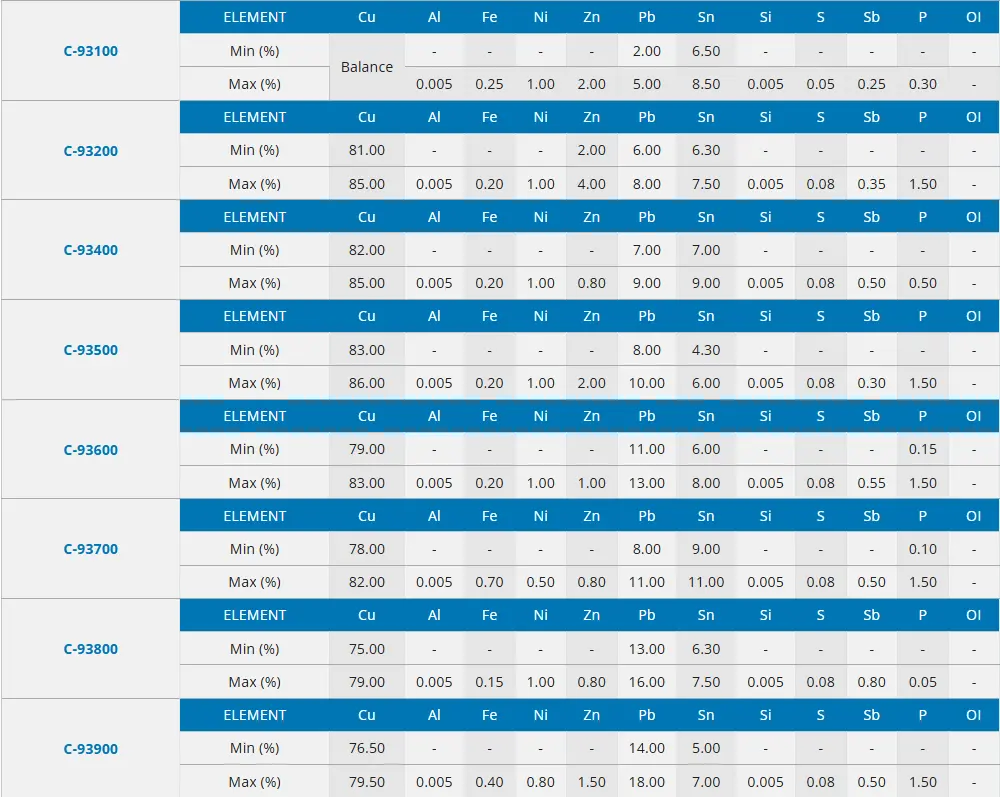

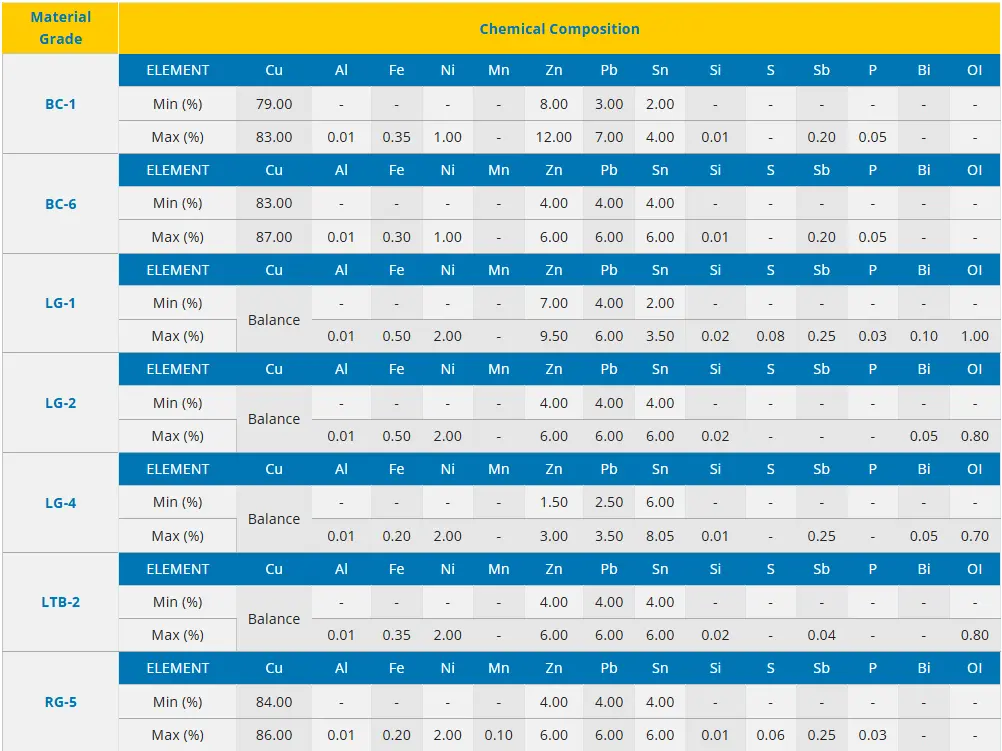

DESCRIPTION

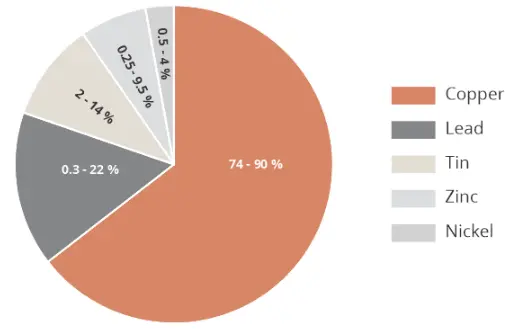

Leaded Tin Bronzes are type of Copper-Tin alloys where Lead is the principal alloying element.

Unlike Tin Bronzes, these alloys contains Lead upto 16% which helps in improving the machinability and pressure tightness of the components.

Nickel and Zinc are also added up to 5% to achieve certain desired properties.

These alloys are a preferred choice when all properties and costs are considered.

PROPERTIES:

Leaded Tin Bronze alloys are superior bearing alloys with good load-carrying capacity and toughness.

Mechanical strength and ductility of these alloys are lower than that of Tin Bronzes, but they impart anti-frictional properties and can be easily machined.

They are generally not subject to dezincification and have reasonable corrosion resistance to seawater and brine.

High Leaded Bronzes are malleable in nature, which enables them to envelope foreign particles, which protects the wear surface of a mating part like a shaft.

Note: OI Means Other Impurities

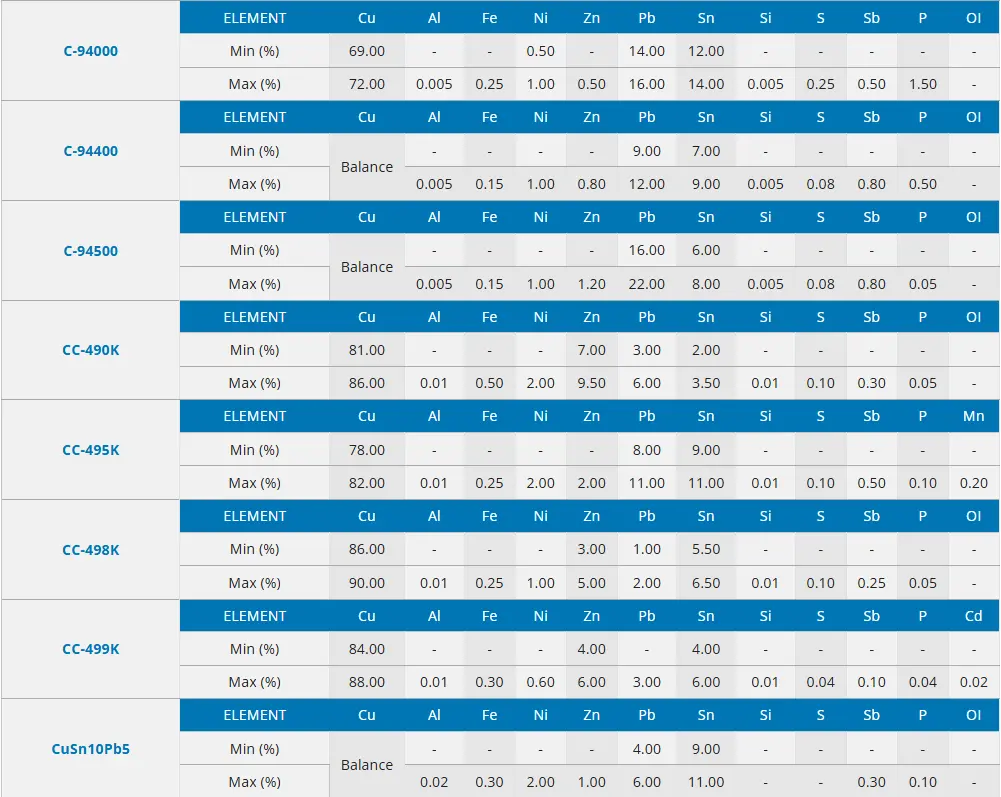

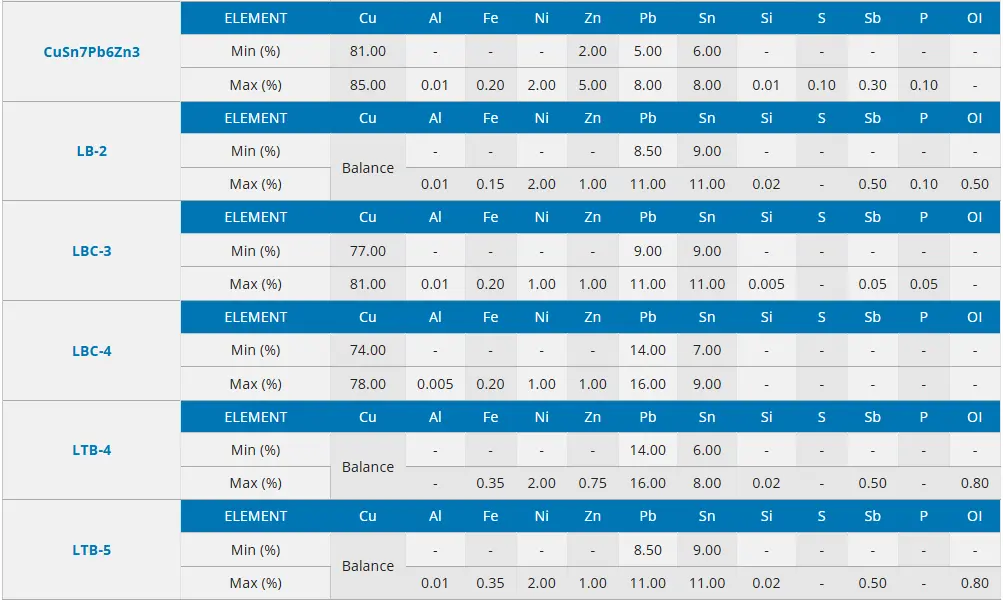

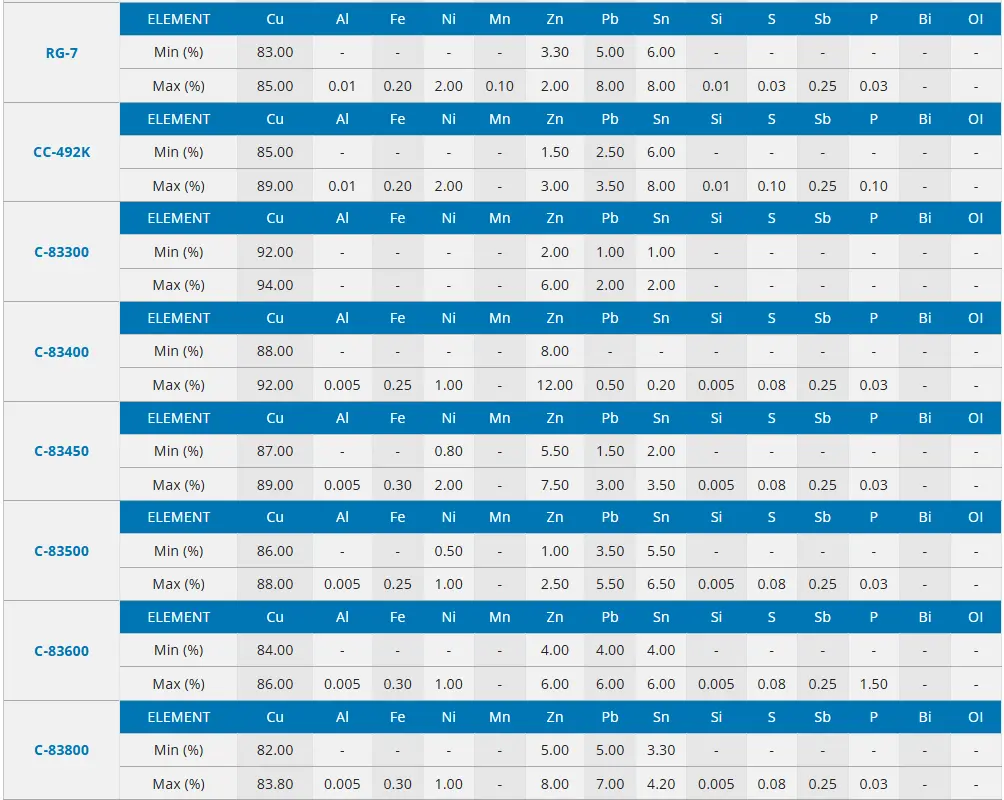

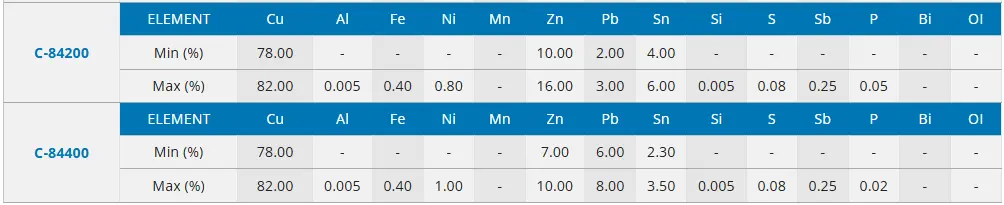

DESCRIPTION

Gun Metal - a type of Bronze is an alloy of Copper, Tin, Zinc and Lead. Originally, it was used extensively for making guns, from which it derived the name "Gun Metal". It is now mainly used for casting machine parts.

The term 'Gun Metal' is applied to a family of copper-based casting alloys containing between 2-11% Tin and 2-10% Zinc.

Other forms include elements as Lead up to 8% which are classified as Leaded Gun Metal. The percentage of these elements slightly varies to produce a wide range of grades used for different purposes.

PROPERTIES:

Gun Metal, because of its special properties, plays a special role among the tin bronze family.

Gun Metal alloys are resistant to atmospheric corrosion from salt water and are not prone to dezincification.

They have been in use for at least 2000 years due to their ease of casting and good strength.

They are known for their reasonable cost, good machining and casting properties.

Lead content ensures pressure tightness and is used for Valves, Plumbing applications and bearings where loads and speed are moderate.

Gun Metal products have good thermal and electrical conductivity, frictional & wear properties, mechanical properties, good machining properties and moderate to high strength.

Gun Metal are noted for its intricate castings and attractive reddish appearance, which makes it a preferred choice for many of the modern statues of the world.

Note: OI Means Other Impurities

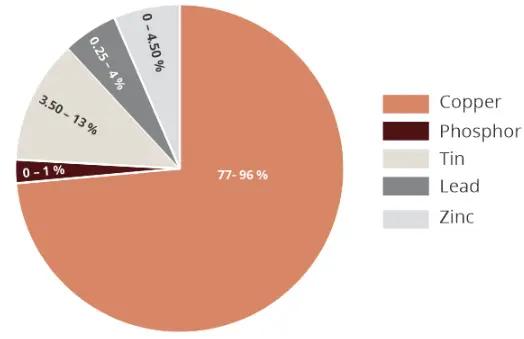

DESCRIPTION

Phosphor Bronze is an alloy containing Copper, Tin and phosphorus.

They are also known as Tin Bronzes, but always have some amount of Phosphorous present to be truly considered as Phosphor Bronze. Historically, it is one of the world's oldest metal alloys, dating back 4000 years.

Phosphor Bronze form a major group of engineering alloys noted for their higher strength and stiffness resulting from the alloyed Tin and phosphorus. The combination of good physical properties, fair electrical conductivity and moderate cost makes it a suitable choice where more expensive metals like beryllium copper are used.

PROPERTIES:

Phosphor Bronze is a fatigue-resistant alloy which can retain its strength over many cycles of loading.

The addition of phosphorus acts as a deoxidising agent during the melting process and reduces the viscosity of the molten metal. This makes it easy to cast and reduce the grain boundaries.

The addition of tin in the alloy increases the corrosion resistance and strength, while Phosphor increases the wear resistance and stiffness of the alloy.

These alloys also offer good thermal and electrical conductivity with excellent spring and plating properties.

The particular blend of mechanical properties, oxidation and low magnetic permeability can be used to the maximum advantage for critical applications.

Chemical Composition

PB-1

Material Grade

PB-2

C-54400

P

0.01

P

0.05

0.25

12

1

0.01

0.5

0.3

0.5

13

0.6

P

3

4

0.01

0.4

Sn

Pb

Zn

Ni

Fe

Al

Cu

ELEMENT

Min (%)

Max (%)

Balance

0.1

0.1

10

0.5

Sn

Pb

Zn

Ni

Fe

Al

Cu

ELEMENT

Min (%)

Max (%)

Balance

0.1

11

0.15

Sn

Pb

Zn

Ni

Fe

Al

Cu

ELEMENT

Balance

Min (%)

Max (%)

0.1

1.5

4.5

3.5

4.5

Note: OI Means Other Impurities

DESCRIPTION

Silicon Bronzes are high copper alloys with a copper content of more than 96%.

The balance element is usually Silicon, but more often a little Manganese, Tin, Iron or Zinc is also added. The combination of these alloys makes it one of the easiest copper-based materials to form/pour.

Silicon Bronzes were originally developed for the chemical industry, but their applications were extended to different fields because of their good casting qualities.

PROPERTIES:

The addition of Silicon in copper alloys helps improve strength and reduce brittleness as compared to other bronze alloys.

Silicon has self-lubricating properties which exhibit excellent bearing and load properties.

They are preferred for their strength, hardness and are readily wieldable, joinable and solderable.

Silicon helps in reducing the melting temperature of the alloy and assists in improving the resistance to corrosion.

With a machinability rating between 30-60%, it can be compensated for by its exceptional formability and weldability.

![]() Note: OI Means Other Impurities

Note: OI Means Other Impurities

DESCRIPTION

Silicon Brasses are a type of high-strength brasses which contain less than 20% Zinc and less than 6% Silicon.

It is a copper-zinc alloy where sometimes Aluminium, Tin or Nickel are added to improve hardness and machining qualities. Silicon is abundant, inexpensive and non-toxic, which can change the characteristics of copper alloys when added.

Silicon brasses are stronger than traditional brasses and can offer benefits in a way that typical copper alloys cannot.

PROPERTIES:

Silicon brasses are typically chosen because of their high strength and high corrosion resistance.

These alloys are preferred over typical brasses because of their lower conductivity.

Castings made of these alloys exhibit moderate strength and very good atmospheric corrosion resistance.

Self-lubricating properties of Silicon make it an ideal choice for connections and fixtures applications.

![]()

Note: OI Means Other Impurities

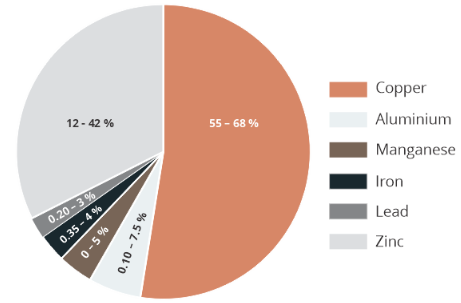

DESCRIPTION

Manganese Bronze is a copper-zinc-based alloy, containing small amounts of Manganese, Aluminium and Iron.

Manganese Bronze is are modification of the Muntz-metal type alloys (60% Copper and 40% Zinc). The Copper-Zinc-Manganese alloy offers one of the highest yield strengths of all cast Copper Alloys at the most economical price.

They are also referred to as High Tensile Manganese Bronze, Manganese Aluminium Bronze, Manganese Brass or High Tensile Brasses.

PROPERTIES:

Manganese Bronzes are characterised by high strength and hardness.

It can withstand stress and corrosion better than other bronzes because of the added manganese, and can boast an impressive strength profile as it is non-heat treatable.

The high fatigue strength, combined with corrosion resistance, gives this alloy preference over other traditional alloys.

The tensile properties of Manganese Bronzes are superior to those of Cast Iron and Cast Mild Steel.

Note: OI Means Other Impurities

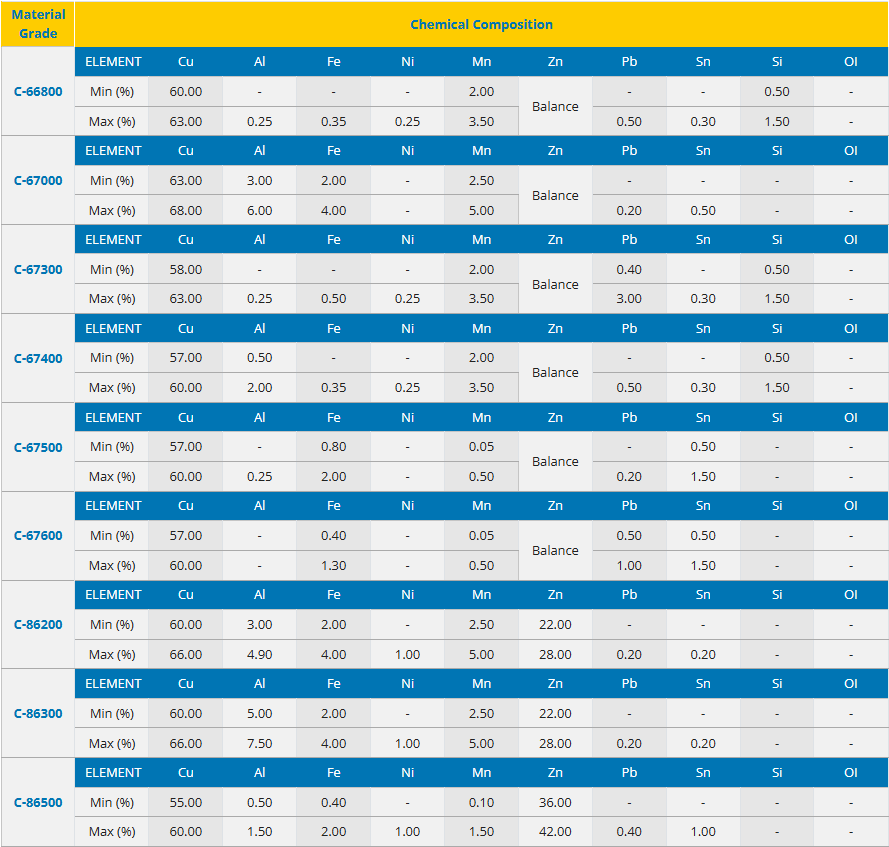

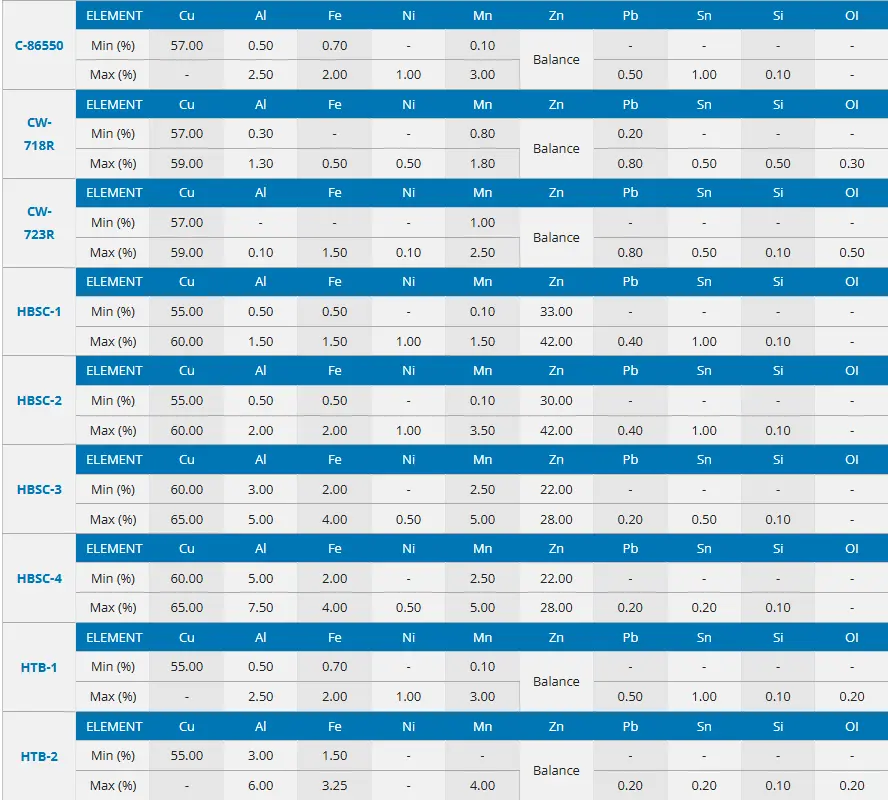

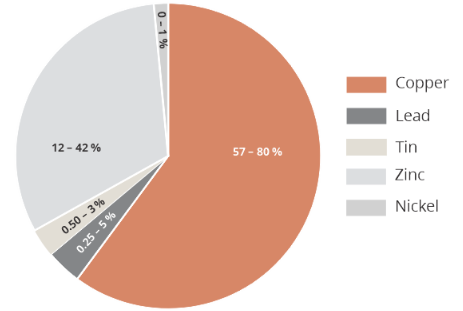

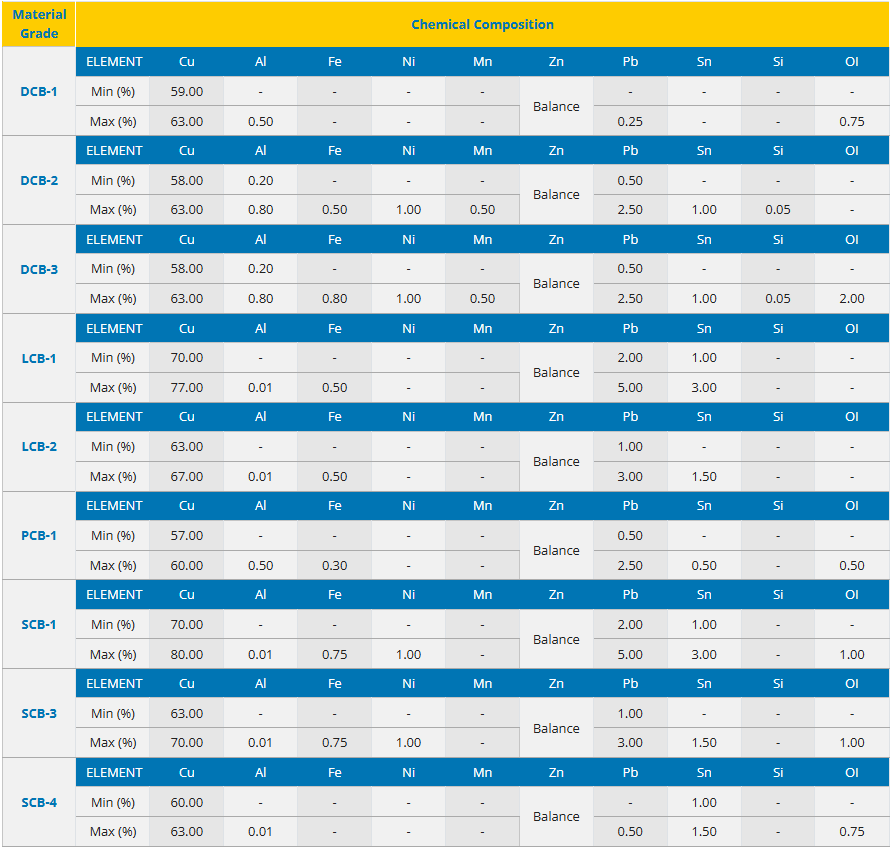

DESCRIPTION

The word "Brass" is the generic term for a wide range of Copper-Zinc alloys.

The proportions of Copper and Zinc are varied to create a range of brass with varying properties. Brasses set the standard by which the machinability of other alloys is measured, and are also available in a wide variety of product forms and sizes to allow minimum machining to finish dimensions.

Widely used in almost every industrial sector, brass is the most commonly used from the Copper alloy family.

PROPERTIES:

Brass has an exceptional combination of unique properties, which include Strength, Ductility, Hardness, Electrical and Thermal Conductivity, Hygiene, Machinability, Wear Resistance, Corrosion Resistance, Colour and Recyclability.

It is more malleable than copper and exhibits low friction. Brasses have a relatively low melting point and are easy to cast.

Unlike steel alloys, brass cannot be hardened by heat treating.

Brasses are not ferromagnetic, which makes it easier to sort them from other metals for recycling.

Note: OI Means Other Impurities